Wavetrain Level Crossing Protection

Reducing risk at passive level crossings

Wavetrain's mission is to reduce risks at the vast number of passive or unprotected level crossings, which represent the single biggest challenge for railway safety. While larger level crossings are typically well-protected, the smaller ones, often located in rural areas, pose a much greater risk. These crossings exist in huge numbers, with 1000s of them around the world. Upgrading individual crossings does not make a significant impact. The solution lies in implementing a system that can quickly reduce risks at scale, at a low cost, and in high volumes, as the real challenge is addressing this issue on a large scale.

Wavetrain - Safety at the Speed of Sound

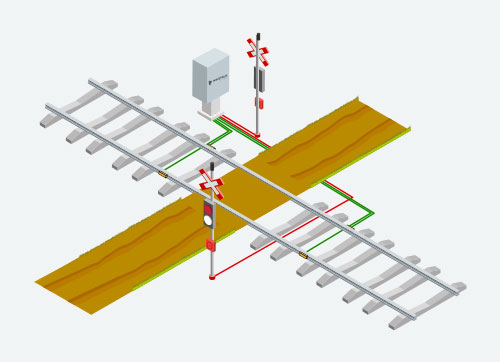

The Wavetrain Level Crossing Protection is a comprehensive, CENELEC SIL 2 & IEC 61508 certified solution that uses acoustic sensors to detect approaching trains. Mounted directly on the rails, the sensors listen for the unique sound energy emitted by trains. The digital data is processed by a nearby Control Unit, which triggers the appropriate warning measures at the correct time. All Wavetrain Systems components are installed at the level crossing site, eliminating the need for extensive cabling and improving track worker safety. This streamlined approach minimizes boots on ballast, reducing maintenance costs and ensuring long-term efficiency.

Key Benefits

Reduce Risk Fast

Installation done in hours, with few parts, and no need for expert skillset.

Adjustable Warning Time

Wavetrain is unique; with a simple change of parameters, warning time can be adjusted in accordance with local requirements.

Reduce Lifecycle Costs

Competitive pricing, less maintenance (no moving parts), less environmental footprint.

Fit & Forget

The system requires a minimum of inspection, is autonomous but can be connected and give real-time status.

Boots Off Ballast

All being installed at the level crossing increases track worker safety and get boots of ballast permanently.

Reduce Service Interruption

With rapid installation at the level crossing, downtime is close to non-existent.

Designed for your Region

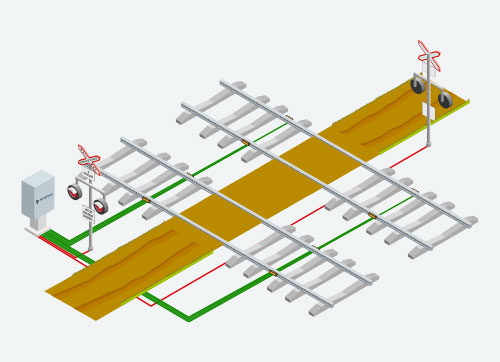

UK Site

Design Example

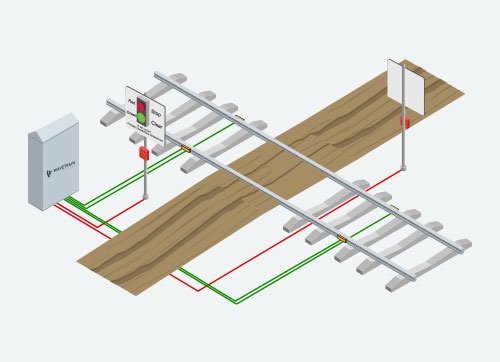

Norway Site

Design Example